For millennia, farming has been a skill-dependent occupation. The size of the yield varied with the farmers’ success at predicting weather patterns, predetermining market demands, and efficiency of their agricultural practices. Smart agriculture introduces data-driven farm operations, for the first time unlocking record output without relying on individual skills or physical work.

Red Flags for Smart Farming

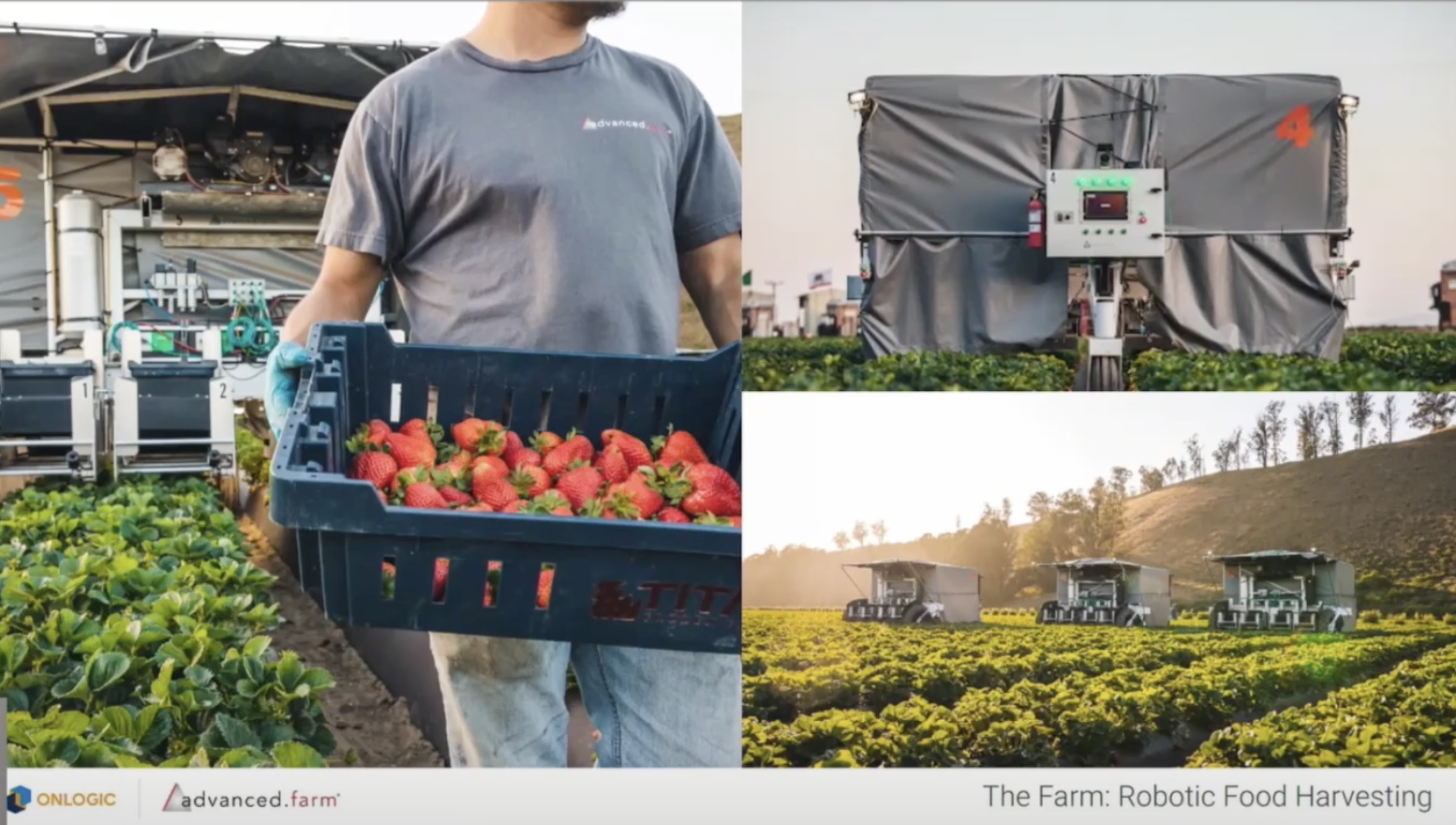

Robotic harvesters, remote monitoring apps, AI-enabled quality control, digital soil mapping and drone-based irrigation are some instances of smart farming methods that are being applied on farms around the globe. These processes have greatly optimized agricultural production and unlocked more revenue for farming companies, besides improving sustainability of certain farming practices.

But, operating at the edge, farming companies face some tailwinds adopting these practices and technologies.

“The edge is far away from the enterprise, the data center or the cloud,” noted Ross Hamilton, systems architect at OnLogic. “It is the area beyond what you can say is a reliable network connection.”

But the problem runs beyond not having decent network connectivity, he said. At the farms, open-air conditions produce an inhospitable environment for computer systems to survive. Weather takes a heavy toll making it fiendishly difficult for the frangible hardware of the data centers to perform.

High-tech farming applications require purpose-built hardware that have been hardened through engineering to be less susceptible to extreme weather conditions. These systems must have the physical resilience to live and operate in exposed environments for extended periods of time.

The key to navigating the challenges at the edge, Hamilton said, is to grasp the extensive complex of edge.

“Latency and bandwidth are all considerations we need to think about, but really, it’s about figuring out what those solutions that have the most impact are, and where they need to be. The hardware aspect of it, the latency of the network, that comes into play as a result of that effort,” he stated.

An Edge-Smart Computing Platform for Rugged Environments

OnLogic is an edge computing hardware company that has built an enduring reputation on its portfolio of industrial-grade edge computers. It’s line of edge devices stand out by the quality of their “look and feel” which include a small form factor, a compact design, and extended life. Being highly configurable and easily deployable, the devices serve as entry points to operating in many edge environments, said Hamilton while presenting OnLogic’s family of computer solutions for farming and mining use cases at the Edge Field Day event in September.

“We don’t think of the edge as the endpoint. We think of it as the starting point.”

OnLogic seeks to drive home the point that many miss. The architectural complex of the edge is unlike traditional IT. It is fraught with a myriad of challenges. Wide temperatures, presence of dust and water, and vibrations threaten to damage most computer systems. In the fields, temperature swings between morning and noon hours are most normal. Robotic pickers cause significant vibrations and shocks as they roll through uneven lands blowing off dust and grime in the air.

OnLogic computers provide a breadth of functions and capabilities for edge use cases such as this. Narrating a customer story, Hamilton explained how OnLogic is helping farms leverage the synergy between smart technology and conventional methods.

The OnLogic Karbon 800 Series, under which all its rugged solutions are listed, is designed to operate in dusty settings, and temperature ranging between -40°C to 70°C. The family boasts a fanless design which makes it more reliable with higher mean time between failures (MTBF). Under the hood, the platform leverages Intel’s embedded processors.

“These SKUs are set out there to live so that they can operate at a much greater level of reliability than your otherwise typical desktops,” he said.

Built-in features allow Karbon devices to interface with motor controllers, and process and export sensor data to dashboards or the cloud via cellular connectivity or mobile uplink. Additionally, the computers feature an internal microcontroller (MCU) which works behind features like ignition sensing, DIO and CAN.

“The integrated programmable MCU has the ability to do external power switch connectivity that you can access via the programmable microcontroller.”

The Karbon series also offers support for AI applications and capabilities through GPU expansion optionality. This allows users to add additional computing hardware to the systems when built-in processors fail to handle the workloads.

Check out OnLogic’s presentations from Edge Field Day to learn more about the Karbon Rugged Computer solutions.